Machining Facility

Our manufacturing facility is setup with the aim to meet growing global demand for swivel joints and hydraulic valves. Continuous plant modernization and capacity upgradation is done to build scale ahead of market growth and serve the customer better.

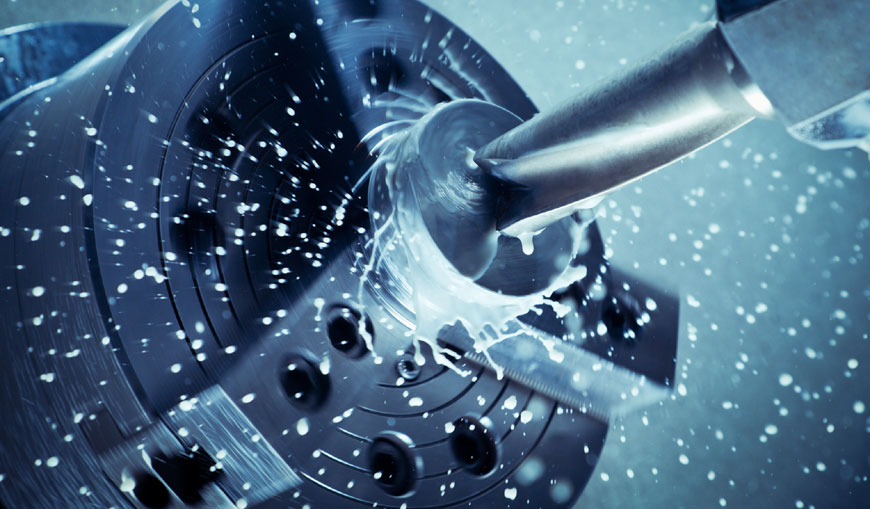

We use best-in-class machinery for CNC turning, CNC milling, honing, burnishing and grinding to achieve the desired geometrical accuracies required to meet the product performance expectations.

The need for additional investments towards new plant machinery or upgradation of existing facilities is regularly evaluated to ensure customer receives best-in-class product.

Assembly & Testing

Our manufacturing techniques are flexible to ensure all of our customer requirements are met even during fluctuating market situations. We use our mechanized assembly line and automated product testing to assist us in meeting the customer requirements.

100% of our parts are tested before being dispatched to customers. This is done to ensure product reliability.

Oil Cleanliness

We believe oil cleanliness is extremely important in ensuring longer life for hydraulic components. To ensure the cleanest possible assemblies to our customers, we utilise a 5-stage oil filtration equipment and high-pressure jet washing station.

Oil cleanliness levels are measured continuously using online particulate counters and sensors providing real-time feedback to our team.

We periodically check for component cleanliness levels using Millipore test and third-party lab validation.